Take into consideration creating standardized templates or formats for documenting validation and verification routines to guarantee consistency and clarity. Entail key stakeholders during the review process to validate results and proposals. Make the most of visualization instruments including graphs, charts, and diagrams to boost knowledge of intricate facts and benefits.

Continued process verification consists of collecting and analyzing data from program output runs and generating necessary adjustments to keep up the validated point out in the process.

The pharmaceutical industry stands on the precipice of a revolution as emerging digital technologies…

It can be worthy of noting that not backing up regularly is without doubt one of the major typical faults. Starting computerized backups can help you save your staff through the nightmare of recreating documents from the ground up.

Just after process design and style and process qualification, the third phase of process validation bargains with setting units to repeatedly make certain that the validated process remains in this kind of condition through regimen production. Ongoing process verification usually incorporates the use of statistical process Command (copyright), the continuous checking and sampling of process parameters and good quality attributes, as well as scheduled servicing of the power, utilities, devices, and connected belongings. It really is important for excellent documentation tactics to get used all through the validation process.

Pharmaceutical validation will involve assessing Every single manufacturing phase making sure that predefined criteria are constantly met. It also requires documenting your complete process, from raw product sourcing to product or service launch.

Validation is producing an evidence trail to point out that an motion, system, or process brings about a reliable and reproducible consequence. Validation is the collection and evaluation of data from the process design phase by way of industrial manufacturing, which establishes scientific evidence that a process or factors of the process can constantly provide a high quality product.

ValGenesis Process Insight combines device operations processes using an integration over the lifecycle. Execute process mapping, electronic continued process verification, and process lifecycle administration within your total merchandise portfolio — all in a single platform.

Even so, the USFDA warned against it simply because they didn't show a clear knowledge of variability sources inside their read more producing processes. Rather, the agency essential them to adjust to unique CGMP regulations, which includes adequately validating producing processes.

The eu Medicines Agency defines a similar process referred to as ongoing process verification. This choice way of process validation is suggested with the EMA for validating processes on the steady basis.

Assessments throughout the generation lifecycle assist warranty that a drug is Protected for use.

Offer a concise summary of The crucial element final results and results on the process validation and verification. Highlight any regions for improvement and where goals were not fulfilled.

By intently monitoring the process, possible difficulties can be resolved proactively, reducing the potential risk of product or service non-conformities and guaranteeing dependable item excellent.

five. On a regular basis evaluate and click here update stakeholders on vital conclusions. Good documentation turns validation endeavours into important references for continual advancement.

Jake Lloyd Then & Now!

Jake Lloyd Then & Now! Daniel Stern Then & Now!

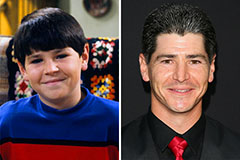

Daniel Stern Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!